Overview products < Manifold units < Modular manifold

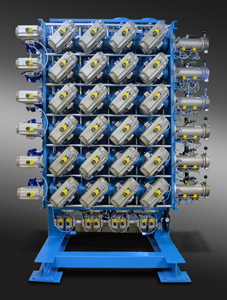

Modular matrix manifold

Unlike the matrix manifold the modular manifold is piggable in both sides. This is a benefit

in case of frequent product changes. All connections to the connected pipelines can be

produced directly and simultaneously. The single valves are mounted to the base frame and

are connected to the four connection pipes by sleeves. The whole of installed valves is

fixed with locking plates which are connected via tension rods. The base frame can be laid

out for horizontal and vertical alignment of the manifold intersections. All dynamic

seals are exchangeable within minutes.

Thanks to the pressure-supported operation of the elastomer-assisted seal system, the manifold's connection must never be switched when pressurised.

Thanks to the pressure-supported operation of the elastomer-assisted seal system, the manifold's connection must never be switched when pressurised.

- Closed and piggable on both sides

- Compact installation size

- No hoses or couplings:

Maximum safety and prevention from leakages and accidents - For pipelines with DN 50, 80 and 100 in one manifold

- Integrated pig catcher unit

- Few movable components – minimal maintenance

- Automatic or manual operation

- Piggable from and to connections

- Modular design for easy extension

- Cost-effective

The manifold unit is a grid pattern distribution node which is piggable to both sides. In its

initial state it consists of two separate pigging lines which are arranged in two levels and

in right angle to each other. By switching the manifold the pigging lines are connected to

each other. At the same time, pig catch inserts are rotated into the pipeline.

The manifold unit is a grid pattern distribution node which is piggable to both sides. In its

initial state it consists of two separate pigging lines which are arranged in two levels and

in right angle to each other. By switching the manifold the pigging lines are connected to

each other. At the same time, pig catch inserts are rotated into the pipeline.

Distribution from 2 to 3 pigging lines, piggable in 2 levels. 2 carriage

actuators switch the single manifold intersections. Here: Continuously in

size DN 50.

A manifold with a distribution from 4 to 6 pigging line in the continuous size DN 100.

For operation it is equipped with single pneumatic actuators. Switching is effected

with rotary actuators. Each manifold intersection has its own rotary actuator.