Overview products < Pigs

Pigs with replaceable lips

In shape and dimensions our pigs are adjusted to the systems of our partner I.S.T.

Molchtechnik but can also very well be used in systems which require similar dimensions.

Since applications and demands through products and systems can considerably vary we also

produce various pig designs.

All pigs consist of a re-usable base body which can consist of one or more parts and a magnet for pig sensing. The base bodies are available in following materials: PA, PP, PE, PVDF and more. The second important component are the guide and scraping lips. These lips are subject to wear because of the contact to the pipeline. This wear depends on the frequency of use but above all on the quality of the pipeline. The pigs underlie a stronger abrasion than the pigs and can therefore be replaced. Depending on the pig's design the replacement can be done by disassembling the pigs or with a special designed tool.

The material of the guide and scraping lips has to be suitable for the product. We can supply special materials and AU, PU, FKM, EPDM, FFKM, ETP and PUR.

All pigs consist of a re-usable base body which can consist of one or more parts and a magnet for pig sensing. The base bodies are available in following materials: PA, PP, PE, PVDF and more. The second important component are the guide and scraping lips. These lips are subject to wear because of the contact to the pipeline. This wear depends on the frequency of use but above all on the quality of the pipeline. The pigs underlie a stronger abrasion than the pigs and can therefore be replaced. Depending on the pig's design the replacement can be done by disassembling the pigs or with a special designed tool.

The material of the guide and scraping lips has to be suitable for the product. We can supply special materials and AU, PU, FKM, EPDM, FFKM, ETP and PUR.

- Cost effective

- Re-usable base body

- Small material consumption for the wear lips. Thus the replacement is cost-effective as well.

The pigs can be moved bi-directionally. They remain in the system until the seal lips are worn,

only then the replacement is effected.

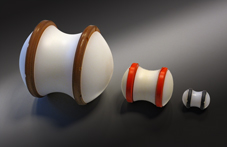

Duo-lip pig with replaceable lips with one-part main body. It has an integrated

magnetic core. The main body is made of PA, the seal lips are made of PU.

The new Duo-pig with replaceable lips. It also consists of a one-part main body with

integrated magnet and is made of PA or AU.

The new Duo-pig with replaceable lips in sizes DN 25 to DN 100 (1“ - 4“).